AKÜN GELSİN olarak öncelikli olarak Bursa ‘nın; Osmangazi, Nilüfer, Yıldırım, Mudanya, Gemlik, Gürsu ilçelerine ve mahallelerine akü ve akü değişimi hizmetimiz olduğu gibi Özel durumlara bağlı olarak, Uludağ, Keles, Kestel, Büyükorhan, Harmancık, İnegöl, Karacabey, Orhaneli, Orhangazi, Mustafakemalpaşa, Yenişehir ilçelerine servisimiz bulunmaktadır.

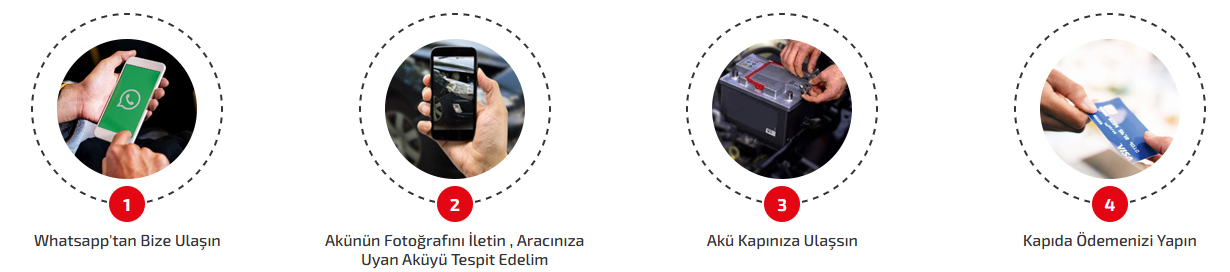

ARA! AKÜN GELSİN!

İnci Akü, Mutlu Akü, Varta Akü, EAS Akü, Çelik Akü, Hugel Akü, Bosch Akü ve Diğer Markalar

Fiyatlarımız Marka ve Modele göre değişmektedir.

Güncel Fiyat ve bilgi için Lütfen bizi arayın

Bursa Osmangazi Mahalleleri

• Adalet Mahallesi

• Adnanmenderes Mahallesi

• Ahmetpaşa Mahallesi

• Akpınar Mahallesi

• Aktarhüssam Mahallesi

• Alaaddin Mahallesi

• Alacahırka Mahallesi

• Alacamescit Mahallesi

• Alaşarköy Mahallesi

• Alemdar Mahallesi

• Alipaşa Mahallesi

• Altınova Mahallesi

• Altıparmak Mahallesi

• Armutköy Mahallesi

• Atıcılar Mahallesi

• Bağlarbaşı Mahallesi

• Bahar Mahallesi

• Barbaros Mahallesi

• Başaran Mahallesi

• Cumhuriyet Mahallesi

• Çekirge Mahallesi

• Çeltik Mahallesi

• Çırpan Mahallesi

• Çiftehavuzlar Mahallesi

• Çirişhane Mahallesi

• Çukurca Mahallesi

• Demirkapı

• Demirtaş Mahallesi

• Demirtaşpaşa Mahallesi

• Dereçavuş Mahallesi

• Dikkaldırım Mahallesi

• Doburca Mahallesi

• Doğanbey Mahallesi

• Doğanevler Mahallesi

• Dosab

• Eğitim Mahallesi

• Elmasbahçeler Mahallesi

• Esentepe Mahallesi

• Fatih Mahallesi

• Fatihsultanmehmet Mahallesi

• Gaziakdemir Mahallesi

• Geçit Mahallesi

• Gülbahçe Mahallesi

• Gündoğdu Mahallesi

• Hacıilyas Mahallesi

• Hamitler Mahallesi

• Hamzabey Mahallesi

• Hocahasan Mahallesi

• Hüdavendigar Mahallesi

• Hürriyet Mahallesi

• Ibrahımpaşa Mahallesi

• İnkaya Mahallesi

• İntizam Mahallesi

• İsmetiye Mahallesi

• İstiklal Mahallesi

• İvazpaşa Mahallesi

• Kavaklı Mahallesi

• Kayhan Mahallesi

• Kemerçeşme Mahallesi

• Kırcaali Mahallesi

• Kızyakup Mahallesi

• Kirazlı Mahallesi

• Kiremitçi Mahallesi

• Kocanaip Mahallesi

• Koğukçınar Mahallesi

• Kuruçeşme Mahallesi

• Küçükbalıklı Mahallesi

• Kükürtlü Mahallesi

• Küplüpınar Mahallesi

• Maksem Mahallesi

• Mehmetakif Mahallesi

• Mollafenari Mahallesi

• Mollagürani Mahallesi

• Muradiye Mahallesi

• Mutluevler Mahallesi

• Nalbantoğlu Mahallesi

• Namıkkemal Mahallesi

• Nilüferköy Mahallesi

• Orhanbey Mahallesi

• Osmangazi Mahallesi

• Ovaakça Mahallesi

• Panayır Mahallesi

• Pınarbaşı Mahallesi

• Reyhan Mahallesi

• Sakarya Mahallesi

• Santral Mahallesi

• Santralgaraj Mahallesi

• Selamet Mahallesi

• Selçukhatun Mahallesi

• Selimiye Mahallesi

• Sırameşeler Mahallesi

• Soğanlı Mahallesi

• Soğukkuyu Mahallesi

• Şehabettinpaşa Mahallesi

• Şehreküstü Mahallesi

• Tahtakale Mahallesi

• Tayakadın Mahallesi

• Tuna Mahallesi

• Tuzpazarı Mahallesi

• Ulu Mahallesi

• Veyselkarani Mahallesi

• Yahşibey Mahallesi

• Yeniceabat Mah

• Yenikaraman Mahallesi

• Yeşilova Mahallesi

• Yunuseli Mahallesi

• Zafer Mahallesi

• Zekaigümüşdiş Mahallesi

Bursa Nilüfer Mahalleleri

• 100 Yıl Mahallesi

• Ahmetyesevi Mahallesi

• Alaaddinbey Mahallesi

• Altınşehir Mahallesi

• Ataevler Mahallesi

• Balat Mahallesi

• Barış Mahallesi

• Beşevler Mahallesi

• Cumhuriyet Mahallesi

• Çalıkhalil Mahallesi

• Çamlıca Mahallesi

• Demirci Mahallesi

• Dumlupınar Mahallesi

• Ertuğrul Mahallesi

• Esentepe Mahallesi

• Fethiye Mahallesi

• Görükle Mahallesi

• Gümüştepe Mahallesi

• Hasanağa Mahallesi

• Işıktepe Mahallesi

• İhsaniye Mahallesi

• İstiklal Mahallesi

• Karaman Mahallesi

• Kurtuluş Mahallesi

• Küçüksanayi

• Kültür Mahallesi

• Minareliçavuş Mahallesi

• Nosab

• Odunluk Mahallesi

• Osb

• Özlüce Mahallesi

• Sakarya Mahallesi

• Üçevler Mahallesi

• Ürünlü Mahallesi

Bursa Yıldırım Mahalleleri

• 152Evler Mahallesi

• 75.Yıl Mahallesi

• Akçağlayan Mahallesi

• Anadolu Mahallesi

• Arabayatağı Mahallesi

• Bağlaraltı Mahallesi

• Baruthane Mahallesi

• Beyazıt Mahallesi

• Çınarönü

• Davutdede Mahallesi

• Davutkadı Mahallesi

• Değirmenlikızık Mahallesi

• Değirmenönü Mahallesi

• Demetevler

• Duaçınarı Mahallesi

• Eğitim Mahallesi

• Emirsultan Mahallesi

• Erikli Mahallesi

• Ertuğrulgazi Mahallesi

• Esenevler Mahallesi

• Fidyekızık Mahallesi

• Güllük Mahallesi

• Hacıseyfettin Mahallesi

• Hacivat

• Hocataşkın Mahallesi

• İsabey

• Kaplıkaya Mahallesi

• Karaağaç Mahallesi

• Karamazak Mahallesi

• Karapınar Mahallesi

• Kazımkarabekir Mahallesi

• Kurtoğlu Mahallesi

• Maltepe Mahallesi

• Mehmetakifersoy Mahallesi

• Mevlana Mahallesi

• Meydancık Mahallesi

• Millet Mahallesi

• Mimarsinan Mahallesi

• Mollaarap Mahallesi

• Musababa Mahallesi

• Namazgah Mahallesi

• Ortabağlar Mahallesi

• Piremir Mahallesi

• Samanlı Mahallesi

• Selçukbey Mahallesi

• Selimzade Mahallesi

• Sıracevizler Mahallesi

• Sinandede Mahallesi

• Siteler Mahallesi

• Şirinevler

• Şükraniye Mahallesi

• Teferrüç Mahallesi

• Ulus Mahallesi

• Umurbey Mahallesi

• Vakıf Mahallesi

• Vatan Mahallesi

• Yavuzselim Mahallesi

• Yediselviler Mahallesi

• Yenımahalle Mahallesi

• Yeşil Mahallesi

• Yeşilevler

• Yeşilyayla Mahallesi

• Yıldırım Mahallesi

• Yiğitler Mahallesi

• Yunusemre Mahallesi

• Zümrütevler Mahallesi

Bursa Mudanya Mahalleleri

• Bademli Mahallesi

• Burgaz Mahallesi

• Camişerif Mahallesi

• Eğitim Mahallesi

• Enverpaşa Mahallesi

• Halilbey Mahallesi

• Halitpaşa Mahallesi

• Hasanbey Mahallesi

• Hasköy Mahallesi

• Mütareke Mahallesi

• Niyazibey Mahallesi

• Ömerbey Mahallesi

• Siteler Mahallesi

• Şükrüçavuş Mahallesi

• Talatbey Mahallesi

• Ülkü Mahallesi

• Yalı Mahallesi

• Yeni Mahallesi

Bursa Gemlik Mahalleleri

• Ata Mahallesi

• Atatürk Mahallesi

• Balıkpazarı Mahallesi

• Cumhuriyet Mahallesi

• Demirsubaşı Mahallesi

• Doktorziyakaya(Dr.Ziyakaya) Mahallesi

• Eşrefdinçer Mahallesi

• Gençali Mahallesi

• Güzelyalı Mahallesi

• Halitpaşa Mahallesi

• Hamidiye Mahallesi

• Hisartepe Mahallesi

• Kayhan Mahallesi

• Memireis Mahallesi

• Orhaniye Mahallesi

• Osmaniye Mahallesi

• Parsbey Mahallesi

• Serbest Bolge

• Siteler Mahallesi

• Şükrüalemdar Mahallesi

• Şükrükaya Mahallesi

• Yeni Mahallesi

Bursa Gürsu Mahalleleri

• Adaköy Mahallesi

• Ağaköy Mahallesi

• Hasanköy Mahallesi

• İstiklal Mahallesi

• Kumlukalanı Mahallesi

• Kurtuluş Mahallesi

• Kurtuluşosb Mahallesi

• Yenidoğan Mahallesi

• Yenidoğanosb Mahallesi

• Zafer Mahallesi